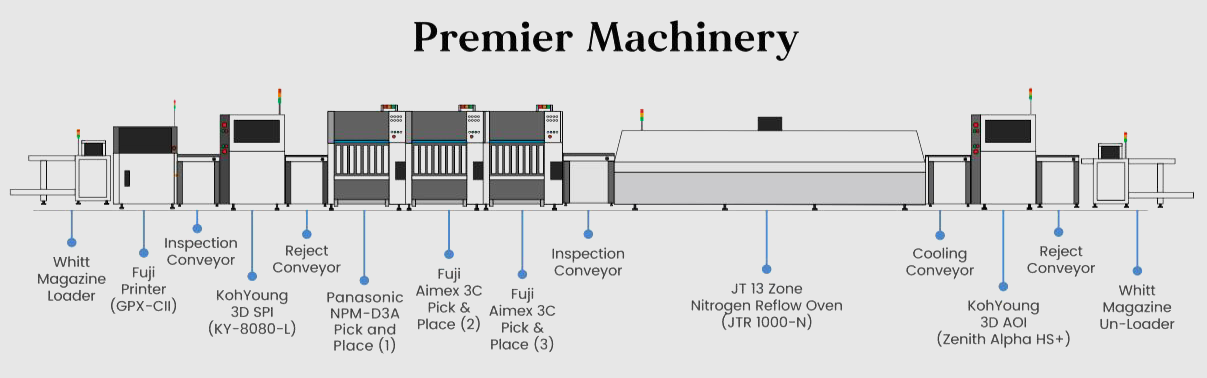

Solder Paste Printer

- Fuji - GPX-CII Automated Solder Paste/Glue Printer.

- Applicable panel size 48 x 48mm to 610 x 610mm.

- Alignment Accuracy: ± 0.010mm, 6σ [CpK≥2.0]

- WetPrinter Accuracy: ± 0.018mm, 6σ [CpK≥2.0]

- Printer Cycle time: 6.0 seconds (including panel loading, unloading, mark reading, mask alignment)

- Auto Paste Dispenser JAR type with Solder Roll Dia Check function.

- Stencil Cleaning: Dry + Wet + Vacuum.

- SPI Closed loop function.

- Local Verifier - with Handy Barcode Scanner.

- Automatic width adjustment.

3D Solder Paste Inspection

- Koh Young inline 3D SPI– KY8080-L.

- Printer close Loop Feedback.

- Camera Barcode reader.

- PCB Warp Compensation: Z Tracking.

- Detects Insufficient Paste, Excessive Paste, Missing‐Paste, Bridging, Shape Deformity, Paste Displacement, Volume, Height, XY Position, Area.

- Koh Young proprietary light projection unit for shadow free effect.

- 4M B/W Digital Camera, 15um X/Y‐resolution (20/25um configurable from factory).

- 0.37um Z resolution.

- SPC Plus software (Statistical Process Control).

- Applicable PCB Size 50mmx50mm to 510mmx510mm.

- No PCB color sensitivity.

- Min. Paste deposit supported up to 3.94 mils.

- Measurement Accuracy: < 1% on Calibration Target.

- Measurement Accuracy: < 3% on PCB.

- Measurement repeatability: < 10% on 01005 deposits @ 6 sigma [with 50% tolerance].

- KSMART LINK Software - Closed loop feedback from AOI to SPI.

Pick and Place Machines

- Fuji- AIMEX IIIc – 2 Robot x 2 Modules with a capacity of 1,03,000 CPH.

- 48 x 48mm to 508mm x 400mm PCB handling capability.

- PBGA, FBGA, Micro-BGA, CSP, Ultra-fine pitch QFP & QFN mounting capability.

- Mounter accuracy of 0.025 mm, Cpk ≥ 1.00 (3σ).

- Supports Fine pitch components (01005 & 0201)

- Intelligent smart feeders (4mm to 72mm & 3 vibratory stick feeders).

- Fuji- AIMEX IIIc with Tray unit for chip & IC/BGA/other components mounting.

- Built‐in Auto Calibration and Hybrid calibration ensures placement accuracy to best level.

- Image processing is through CCD camera.

- FUJI Intelligent Feeders are of Variable pitch, electrically driven, Common for Paper & Emboss, Common for partsfrom 0402 mm (01005”) to 3225mm (1210”) parts size.

- Three Extra feeder carts for quick change over.

- Board level Traceability.

- Free Feeder Allocation.

Pick and Place Machine

- Panasonic NPM-D3A Pick and Place Machine with 92500 CPH.

- Board handling capacity of 50mm × 50mm ~ 510mm × 590mm.

- Mounter accuracy of 0.025 mm, Cpk ≥ 1.00 (3σ).

- Supports Fine pitch components (01005 & 0201).

- Intelligent smart feeders (4mm to 32mm).

- Two Extra feeder carts for quick change over.

- Built - in Auto Calibration and Hybrid calibration ensures placement accuracy to best level.

- Image processing is through CCD camera.

- Board level Traceability.

- Free Feeder Allocation.

Reflow Oven

- JTR-1000N Reflow Oven with Nitrogen Ready.

- Heating zones 10 Top and Bottom.

- Cooling Zones 3 Top and Bottom .

- In-built Thermal Profiler.

- Both Mesh & Chain Conveyors inbuilt.

- Automatic Lubrication System (Including Automatic chain oilers).

- Board Drop / Board Count Sensor with Animation.

- Reflow Profiler KIC –X5 9 channel with Carrier available.

- Camera Barcode Reader

3D Automated Optical Inspection(AOI)

- Koh Young Inline 3D Automated Optical inspection (AOI)ZENITH ALPHAHS+.

- 3D Inspection: Missing, Offset, Billboarding, Tombstone, Coplanarity, Solder Joint (insufficient, excessive), Lifted Leads, Bridging, "No‐Pops" Polarity.

- 2D Inspection: "Wrong Part" using Optical Character Verification (OCV/R), Polarity.

- Camera Barcode Reader.

- 8M Pixel 3D Camera.

- Maximum board handling capability of up to 490 x 510mm.

- OCV & OCR capability.

- 25mm 3D Height Inspection capability.

- 5 Way 3D Projector Lighting System.

- Auto Programming option & Offline programming software.

- KSMART LINK Software - Closed loop feedback from AOI to SPI.